Products

Mining high-tensile round link chains

Category

Mining high-tensile round link chains

Product Details

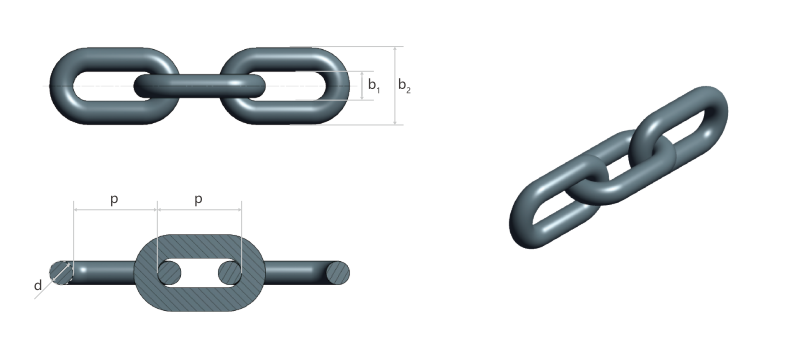

Mining Round Link Chain

Manufacture standards

The mining round link chains produced by Gelin can meet the dimension and all the mechanical performance requirements of GB/T 12718; DIN 22252 and other standards

Scope of application

The mining high-strength circular-ring chains produced by Gelin are mainly applied to coal mine scraper conveyors, loaders and coal plough

Friendly reminder

Users should choose the suitable coating and corrosion prevention methods according to the working condition and storage conditions of individual mines;

Any kind of anti-corrosion coating method may reduce the performance of chains;

Size

|

Chain Standard sizes

|

Diameter d |

Pitch P |

Inner width b1 minimum |

Outer width b2 maximum value |

Weight |

| [mm] | [mm] | [mm] | [mm] | [mm] | [kg/m] |

| 22X86 | 22±0.7 | 86±0.9 | 26 | 74 | 9.5 |

| 24X86 | 24±0.7 | 86±0.9 | 28 | 79 | 11.6 |

| 26X92 | 26±0.8 | 92±0.9 | 30 | 86 | 13.7 |

| 30X108 | 30±0.9 | 108±1.1 | 34 | 98 | 18.0 |

| 34X126 | 34±1.0 | 126±1.2 | 38 | 109 | 22.7 |

| 38X126 | 38±1.1 | 126±1.2 | 42 | 121 | 30.1 |

| 38X137 | 38±1.1 | 137±1.4 | 42 | 121 | 29.0 |

| 42X146 | 42±1.1 | 146±1.5 | 46 | 133 | 36.0 |

Note: The surface delivery state of Green products is natural black anti-rust treatment, other requirements from customers need to be negotiated separately;

*Circular chain used in reloader, scraper conveyor, coal plow

Mining Ring Chain

Circular-ring chain with optimized strength

Grade B, C, C+, D

Based on relevant circular-ring chain manufacture standards like GB, DIN and PN, to better serve customers and meet the increasingly complex working conditions in the coal exploration wells, engineering technicians of Gelin have developed grade C+ (>900MPA) and grade D (>1050MPA) circular-ring chains. After reinforcement design, chains have higher strength and wear-resistance performance. Such high-strength chains are made of alloy materials with non-traditional manufacture process. The impact toughness will not be reduced, while achieving higher strength. Different grades of circular-ring chains are applicable to different working conditions. Especially the grade D chains have high hardness and higher tensile strength. Since the hardness is improved, chains are more sensitive to stress corrosion. They are likely to be affected by stress corrosion pits and other environments during service, so it is not suggested that they are applied in strongly corrosive environments.

Table of Strength Characteristics of Each Grade of Chain

Depending on the mine environment and storage conditions, we offer a variety of surface treatments:

Depending on the mine environment and storage conditions, we offer a variety of surface treatments:

- Mechanical stress relief enhanced protection

- Rust-resistant protection

- Hot dip galvanized protection

- Anti-rust and anti-corrosion protection by surface oxidation

Note: The surface delivery status of Green products is: surface oxidation and rust prevention, corrosion resistance protection---it is a natural black rust prevention treatment method.

Mechanical behavior

|

Chain Standard sizes dxp |

chain grade | force |

Under test force Maximum elongation |

Under breaking force Minimum elongation |

Minimum bending deflection f | Minimum fatigue strength | |

| Test force | Minimum breaking force | ||||||

| [mm] | [kN] | [kN] | [%] | [%] | [mm] | [Cycles] | |

| 22X86 | B | 380 | 490 | 1.4 | 12 | 22 | 50 000 |

| C | 490 | 610 | 1.6 | 12 | 22 | 70 000 | |

| D | 610 | 760 | 1.9 | 16 | 22 | 90 000 | |

| 24X86 | B | 460 | 570 | 1.4 | 12 | 24 | 50 000 |

| C | 580 | 720 | 1.6 | 12 | 24 | 70 000 | |

| D | 720 | 900 | 1.9 | 16 | 24 | 90 000 | |

| 26X92 | B | 540 | 670 | 1.4 | 12 | 26 | 50 000 |

| C | 640 | 850 | 1.6 | 12 | 26 | 70 000 | |

| D | 790 | 1060 | 1.9 | 16 | 26 | 90 000 | |

| 30X108 | C | 900 | 1130 | 1.6 | 12 | 30 | 70 000 |

| D | 1130 | 1410 | 1.9 | 16 | 30 | 90 000 | |

| 34X126 | C | 1160 | 1450 | 1.6 | 12 | 34 | 70 000 |

| D | 1450 | 1810 | 1.9 | 16 | 34 | 90 000 | |

| 38X126 | C | 1450 | 1810 | 1.6 | 12 | 38 | 70 000 |

| 38X137 | D | 1810 | 2 270 | 1.9 | 16 | 38 | 90 000 |

| 42X137 | C | 1770 | 2 220 | 1.6 | 12 | 42 | 70 000 |

| 42X146 | D | 2 220 | 2 770 | 1.9 | 16 | 42 | 90 000 |

*Draft chains for scraper conveyors, transfer machines, and coal plows

Parameter

The fatigue resistance T (number of cycles) and impact test KV[J] can meet the GB/T12718, DIN22252 and PN-G-46701 standards as well as technical conditions of Gelin.

To achieve good performance of chains in practical work, the hardness distribution at each part of chains is different.

The hardness of the arc part for both the circular-ring chain or compact chain where it meshes with the chain wheel and chain rings connect should be high enough to resist wear, and the toughness of the straight side of chain rings should be improved, so the hardness of the straight side should be a little lower than that of the arc part.

-

- high-strength

- chain

Related products

Sincerely look forward to working with you!

*The relevant information you submit is only for business communication with our company; our company solemnly promises not to provide any personal privacy information about you to third parties; please do not submit it if you are concerned.